|

The below photo's and information was taken from Dave's research & testing in the late 80's ((except where noted by double parentheses)). If you have any questions, comments, concerns, etc. please feel free to contact him directly. Dave Bauerle |

DeLorean Pivot Bolt Support

|

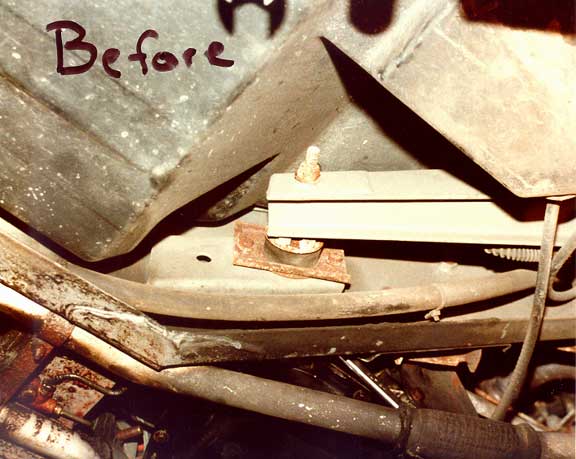

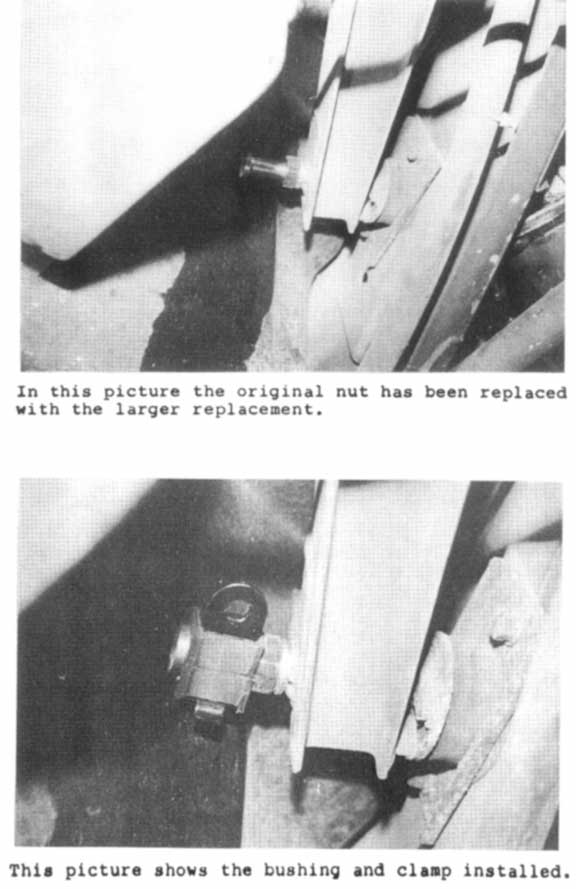

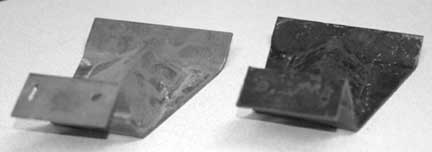

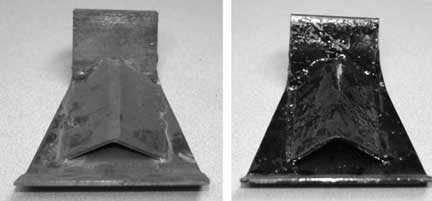

"Our support connects to the outer portion of the pivot bolt and the lower pinchweld of the frame. This provides support to both sides of the trailing arm. Basically this will double the load capacity of the bolt. Keep in mind that if the support did fail in any way the arm would still be supported by its original design. Also, if the original design failed, the support kit would hold the trailing arm by itself, providing a back-up safety feature. The support bracket is constructed from 1/8 inch steel with an angled gusset welded to one side to increase its rigidity. It is then coated for protection. The bottom of the support is bolted to the vehicle's frame. The top is connected to the trailing arm pivot bolt via a rubber bushing and steel clamp. The bushing allows for normal arm movement and insulates road noise from the car. The bushing is connected to the pivot bolt by a specially made nut that replaces the original nut. The original nut is 19 millimeters across whereas the replacement is 25 millimeters, nearly 30% larger. The nut is made from 12L14 steel and then case hardened. The nut is then blackoxide coated for corrosion protection." |

|

|

|

|

The two above shots "are both views from under the vehicle showing the support kit completely installed. Note that the support bracket is made wider where it bolts to the frame. This was done to stabilize the support and spread teh load over a larger area on the vehicle frame." |

|

|

|

|

|

|

|

|

|

|

|

|

|

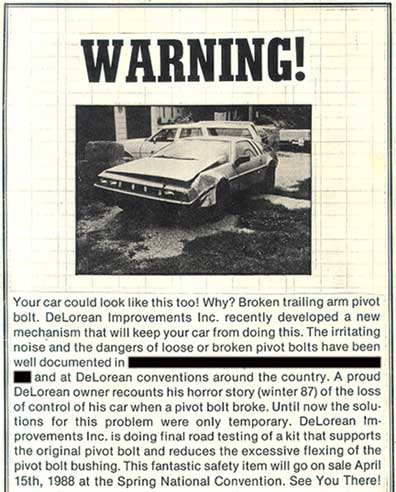

((The original ad below was considered a 'scare tactic' by a certain asphalt segregationist. Never the less, it is the truth and no matter what option one takes to fix this problem it should never be ignored. The name just used comes from me alone and NOT from Dave Bauerle.)) |

|

|

|